If you’ve come across the word pappedeckel and wondered what it actually means, you’re not alone. This term appears often in German packaging, bookbinding, and craft industries, yet many English speakers find it confusing.

In this guide, you’ll learn what pappedeckel is, how it’s used, how it compares to cardboard, and why it plays a big role in everyday products. Everything is explained in plain, human language—no jargon, no fluff.

What Is Pappedeckel?

Pappedeckel is a German word that refers to thick, rigid cardboard made from pressed paper fibers.

In English, pappedeckel is commonly translated as:

-

Paperboard

-

Greyboard

-

Thick cardboard

-

Binding board

Unlike thin paper or flexible carton, this type is firm, stable, and designed to hold its shape.

Origin of the Word Pappedeckel

The word comes from German:

-

“Pappe” = paper or cardboard

-

“Deckel” = cover or lid

It literally means “cardboard cover,” which makes sense because it’s often used as a protective or structural layer.

What Is Pappedeckel Made Of?

This Pappedeckel is made mainly from recycled paper fibers, which usually come from old newspapers, used cardboard, and scrap paper. Instead of being discarded, these fibers are repurposed to create strong and durable sheets.

During production, the paper is mixed with water to form a soft pulp. This pulp is then pressed into thick sheets under heat and pressure, removing moisture and packing the fibers tightly. The result is a solid, firm board that holds its shape well.

Most sheets do not contain plastic or metal, relying on natural fiber bonding to maintain strength. This gives the board a raw, natural appearance and a rigid structure that resists bending.

Because it is made from recycled materials, the board is eco-friendly. It can be recycled again and naturally decomposes over time, making it a sustainable choice for book covers, packaging, folders, and craft projects.

How Pappedeckel Is Manufactured (Step-by-Step)

The production of pappedeckeltransforms recycled paper into a dense, rigid board used for books, packaging, and crafts. Each stage is carefully controlled to ensure consistent thickness, strength, and smooth surface, making the material reliable for professional and creative applications.

Step 1: Collection and Sorting of Paper

The process begins with recycled paper. Manufacturers gather:

-

Old newspapers

-

Used cardboard

-

Paper offcuts from printing and packaging

These materials are carefully sorted by quality and fiber type. Removing impurities like plastics, metal clips, or tape ensures the sheets are smooth, strong, and free from weak spots.

Step 2: Pulping the Paper

The sorted paper is shredded and mixed with water to create a smooth slurry. This paper pulp may include natural binders to strengthen fiber bonds. Pulping transforms ordinary paper into a malleable base, ready to be pressed into dense, durable boards.

Step 3: Pressing the Pulp Into Sheets

The wet pulp is spread evenly and compressed using mechanical presses. Pressure removes excess water and bonds fibers tightly, producing rigid sheets. This step determines thickness and durability. Unlike normal cardboard, ensuring the material holds its shape under pressure.

Step 4: Drying the Boards

Sheets are dried using heated rollers or industrial ovens. Controlled temperature prevents warping or cracking while reducing moisture. The drying process gives the boards a lightweight strength, making them easy to handle while remaining firm.

Step 5: Cutting and Sizing

Once dried, sheets are cut to standard dimensions:

-

Common sizes include sheets for books, boxes, or crafts.

-

Thickness can vary depending on use:

-

1–2 mm for notebooks and folders

-

2–4 mm for hardcover books and gift boxes

-

5 mm or more for heavy-duty packaging

-

Precision cutting ensures uniform thickness, which is crucial for products that rely on exact dimensions, like hardcover books.

Step 6: Optional Surface Treatments

Some sheets receive lamination, fabric wrapping, or decorative paper for aesthetics and durability. Coatings protect against moisture and wear, enhancing appearance without weakening the board. These treatments make pappedeckel ideal for premium products, crafts, or book covers requiring both strength and visual appeal.

Step 7: Quality Control

Each sheet undergoes careful inspection for thickness, surface smoothness, fiber consistency, and overall strength. Only boards that meet strict standards are approved. Quality control ensures the material is consistent, durable, and ready for professional, artistic, and industrial applications.

Step 8: Packaging and Distribution

Finally, pappedeckel sheets are stacked, packaged, and labeled:

-

They may be bundled for wholesale supply to manufacturers.

-

Some are cut to custom dimensions for specific clients.

-

Eco-friendly factories ensure minimal waste and recyclable packaging.

Common Thickness Levels of Pappedeckel

-

1.5–2 mm – folders, notebooks

-

2.5–3 mm – hardcover books

-

3–4 mm – premium boxes, frames

-

5 mm+ – heavy-duty packaging

Thicker sheets provide stronger structural support, while thinner boards are suitable for lighter applications.

Main Uses of Pappedeckel in Everyday Life

Although the word pappedeckel may sound unfamiliar, it’s part of many products we use daily. Its strength, durability, and eco-friendly properties make it versatile across multiple industries. Here’s where it shows up most often:

1. Bookbinding and Publishing

One of the most common uses of pappedeckel is in hardcover books. The rigid board forms the structure of the cover, protecting pages and giving the book a premium feel. Hardcover books wouldn’t last as long without this kind of support.

It is also used for notebooks, planners, and luxury journals, where durability and professional appearance are essential.

2. Packaging Industry

Pappedeckel cardboard is widely used in premium packaging. Electronics, perfumes, cosmetics, and gift boxes often rely on them for stability and protection.

Their firmness prevents products from bending or breaking during shipping, while still being lightweight. Some are laminated or wrapped to enhance appearance and maintain eco-friendliness.

3. Office and School Supplies

Many office and school items contain pappedeckel sheets as backing or reinforcement. Examples include:

-

File folders

-

Clipboards

-

Ring binders

-

Drawing pads

These materials keep documents flat and protected while remaining easy to handle.

4. Arts, Crafts, and DIY Projects

Crafters and hobbyists love pappedeckel because it is easy to cut, paint, and shape. It’s ideal for making:

-

Handmade picture frames

-

Model structures

-

Decorative signs

-

Custom notebooks

Its smooth yet firm surface allows for creative applications that regular cardboard cannot support.

5. Specialty Applications

Beyond books, packaging, and crafts, pappedeckel material is also used in:

-

Puzzle boards

-

Presentation folders

-

Product inserts

-

Protective inserts in boxes

Its versatility stems from a combination of rigidity, lightweight nature, and eco-friendliness, making it a preferred material in many niche industries.

Pappedeckel vs Cardboard vs Carton

Many people confuse pappedeckel, cardboard, and carton, but they are not the same. Understanding the differences helps you choose the right material for books, packaging, crafts, or office use.

1. Pappedeckel

Pappedeckel is a thick, dense, and rigid paperboard. It is usually made from compressed recycled paper fibers and is designed to hold its shape.

Key features:

-

Very firm and strong

-

Smooth, matte surface

-

Often used in hardcover books, luxury packaging, and craft projects

-

Eco-friendly and recyclable

Think of pappedeckel as the “premium” version of cardboard—sturdier and more precise.

2. Cardboard

Cardboard is a more general term for paper-based material used for boxes and packaging. It comes in multiple types, such as single-layer or corrugated cardboard.

Key features:

-

Medium strength

-

Often has corrugated layers for shipping boxes

-

Flexible enough for folding and stacking

-

Commonly used in shipping boxes, storage containers, and simple packaging

Compared to pappedeckel, cardboard is less rigid and not ideal for projects that require precise shape retention.

3. Carton

Carton usually refers to thin paperboard used to make packaging for food and consumer goods, like cereal boxes or milk cartons. It is lighter and less dense than both pappedeckel and cardboard.

Key features:

-

Lightweight and foldable

-

Easy to print on

-

Not very strong or rigid

-

Commonly used for food packaging, drink cartons, and small retail boxes

Carton prioritizes printing quality and lightness over durability.

Quick Comparison Table

| Feature | Pappedeckel | Cardboard | Carton |

|---|---|---|---|

| Thickness | Thick & rigid | Medium | Thin |

| Strength | High | Medium | Low |

| Flexibility | Low | Moderate | High |

| Corrugation | None | Often corrugated | None |

| Common Use | Books, luxury packaging, crafts | Shipping boxes, storage | Food & retail packaging |

| Surface | Matte, smooth | Rough or corrugated | Smooth, printable |

Summary

-

Pappedeckel = strong, dense, premium paperboard

-

Cardboard = general-purpose, medium-strength material

-

Carton = lightweight, printable, for food and consumer products

Choosing the right material depends on strength, appearance, and purpose. For long-term durability and professional appearance, pappedeckel is usually the best choice.

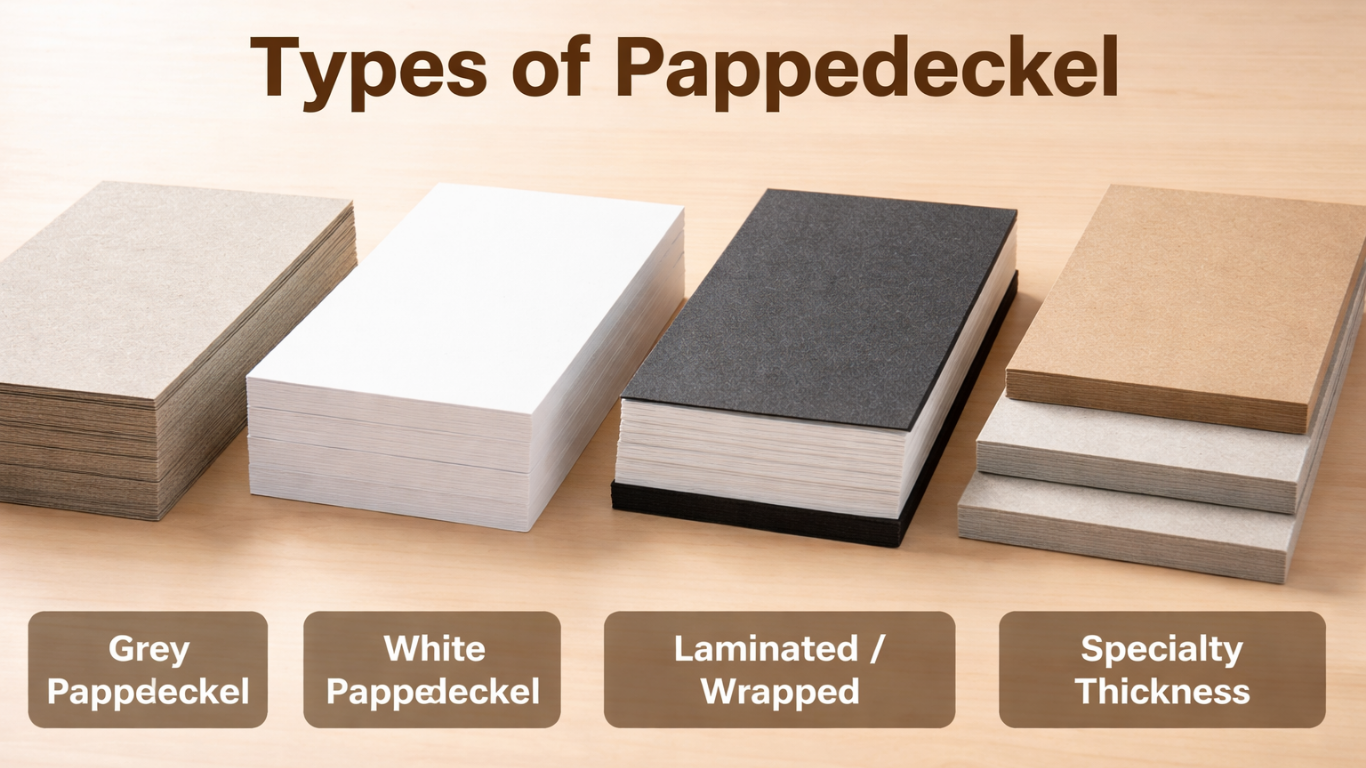

Types of Pappedeckel

Not all pappedeckel boards are the same. Different types are designed to suit specific uses, from bookbinding to premium packaging or craft projects. Understanding the differences helps you choose the right board for your needs.

1. Grey Pappedeckel

Grey pappedeckel is the most common type. It has a neutral grey color and a sturdy, dense structure, making it ideal for:

-

Hardcover books

-

Folders and notebooks

-

Basic packaging

This type is cost-effective and widely available, which makes it the standard choice for everyday applications.

2. White Pappedeckel

White pappedeckel is used when a cleaner, brighter appearance is desired. Its smooth surface makes it perfect for:

-

Premium packaging

-

Art and craft projects

-

Display boards

The white finish can also be printed or decorated, giving products a more polished and professional look.

3. Laminated or Wrapped Pappedeckel

Some pappedeckel sheets are laminated or wrapped with paper, fabric, or decorative coatings. This type is commonly used in:

-

Luxury book covers

-

High-end gift boxes

-

Decorative presentation boards

Lamination adds extra durability and visual appeal, while the core board still provides the rigid support that pappedeckel is known for.

4. Specialty Thickness Boards

Pappedeckel is also available in various thicknesses for niche applications:

Thin boards (1–2 mm): Light folders, notebooks, and craft projects

Medium boards (2–4 mm): Hardcover books, decorative boxes

Thick boards (5 mm+): Heavy-duty packaging, puzzle boards, and structural craft projects

Choosing the right thickness ensures the board can handle its intended use without bending or breaking.

Is Pappedeckel Eco-Friendly?

Pappedeckel is considered an environmentally responsible material because it is made primarily from recycled paper fibers. Unlike plastic or metal, it doesn’t rely on non-renewable resources, making it a sustainable choice for both businesses and consumers.

Made from Recycled Paper

The core of the board comes from recycled paper. Old newspapers, cardboard, and paper scraps are given a second life. Using these fibers reduces the need for cutting down new trees and minimizes waste in landfills, supporting a circular economy.

Biodegradable and Recyclable

Unlike many synthetic boards, this paperboard is fully biodegradable. It breaks down naturally over time and can be recycled again, reducing environmental impact. Products made from it are less likely to contribute to long-term pollution.

Lower Carbon Footprint

Since the board is made from paper rather than plastics or metals, its production requires less energy and produces fewer carbon emissions. This makes it a greener alternative for:

-

Book covers

-

Packaging

-

Office supplies

-

Craft materials

Eco-Friendly Branding

Many modern brands choose this material to showcase sustainability. Using it signals a commitment to the environment while still providing durable and high-quality products.

Why Businesses Prefer Pappedeckel

Businesses love pappedeckel because it is strong and durable. It protects products during shipping and gives packaging a professional, high-quality feel that customers notice.

Another reason is versatility. It can be used for books, boxes, folders, or custom inserts, and can be easily laminated, wrapped, or printed to match branding.

Finally, it is eco-friendly. Made from recycled paper and fully recyclable, it supports sustainability goals while helping businesses reduce environmental impact and manage costs efficiently.

How to Identify Pappedeckel Instantly

Recognizing pappedeckel is easier than it sounds once you know what to look for. First, check the rigidity. It is stiff and holds its shape, unlike regular cardboard that can bend easily.

Next, examine the surface and edges. It usually has a smooth or slightly fibrous surface, with clean edges and no visible corrugated layers. The board feels dense and solid when you press it lightly.

Finally, consider the weight and thickness. Pappedeckel is heavier and thicker than normal paper or cardboard, even in smaller sheets. If it feels like a hard book cover or a strong backing board, you’ve likely found the right material.

What does pappedeckel mean in English?

It means thick cardboard or paperboard used for structure.

Is it stronger than regular cardboard?

Yes, it is thicker, denser, and more rigid.

Where is pappedeckel commonly used?

Books, premium packaging, folders, crafts, and office supplies.

Is it recyclable?

Yes, it’s fully recyclable and biodegradable.

What types of pappedeckel exist?

Grey, white, laminated/wrapped, and various thickness boards for different uses.

Final Thoughts

Pappedeckel may seem like a simple material, but it plays an important role in everyday life. From hardcover books and premium packaging to crafts and office supplies, its strength, durability, and eco-friendly nature make it a reliable choice.

Understanding this material helps you appreciate the quality behind the products you use every day and make smarter choices—whether for buying, crafting, or designing.

Its combination of versatility, sustainability, and professional appeal ensures that it will remain a preferred material across industries for years to come.